I. Awareness Stage: Navigating the New Era of Sustainable Sip Solutions

The Plastic Predicament: Why Your Business Can’t Ignore Single-Use Straws Anymore.

Startling statistics paint a clear picture: every year, billions of plastic straws contribute to the escalating crisis of plastic pollution, choking our oceans and ecosystems. Beyond the ecological damage, consumers are increasingly aware and concerned about the environmental toll, demanding businesses take responsibility. This awareness is driving a global shift, with consumers actively seeking out sustainable alternatives and governments imposing stricter regulations on single-use plastics.

Traditional plastic straws, once symbols of convenience, are now liabilities. Ignoring this shift is no longer a viable option; the market demands sustainable alternatives, and businesses must adapt to thrive.

Beyond Plastic: Introducing the Next Generation of Compostable Straws.

Compostable straws represent a significant step towards environmental responsibility. These innovative products are designed to break down naturally in composting environments, reducing the harmful impact of single-use plastics. Among the leading eco-friendly materials are sugarcane and PHA (Polyhydroxyalkanoates), each offering unique benefits for businesses.

A Brief History of the Sip: From Ancient Reeds to Modern Sustainability.

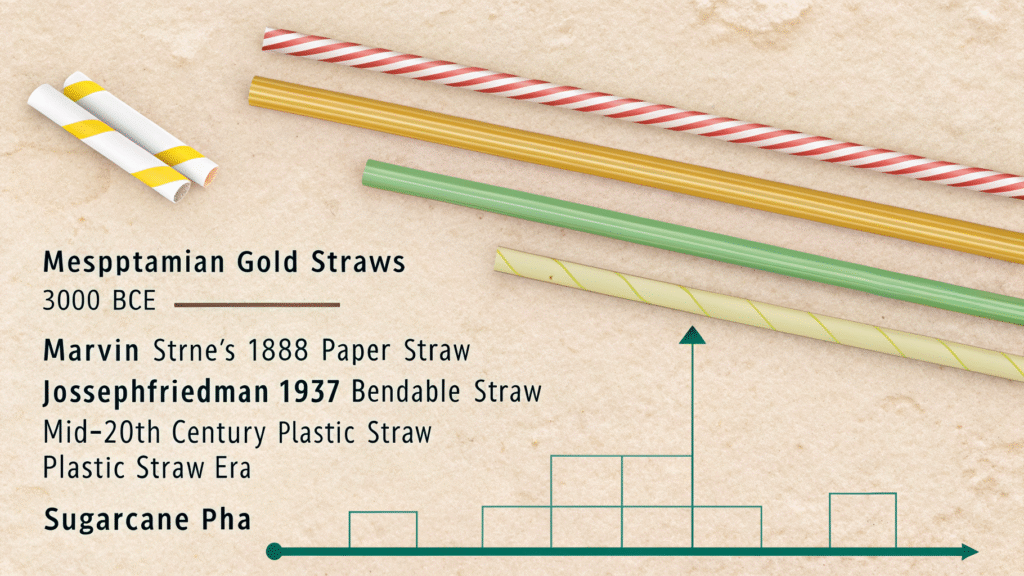

- Early Innovations: The earliest known drinking straws date back over 5,000 years to ancient Mesopotamia, where Sumerians used ornate straws made from gold and wood. In 16th century Argentina, metal straws called “bombillas” served as both drinking implements and sieves.

- The Rise of Paper: The late 19th century saw the introduction of rye grass straws, but their tendency to disintegrate led to Marvin Stone’s 1888 patent for the modern paper drinking straw. Joseph Friedman further innovated with the flexible straw in 1937.

- The Plastic Reign (Mid-20th Century): Mass production in the mid-20th century made inexpensive plastic straws ubiquitous, favored for their durability.

- The Environmental Awakening (Post-2000s): Growing environmental awareness led to bans and a surge in demand for sustainable alternatives.

- The Current Imperative: Evolving environmental consciousness and regulatory pressures are forcing businesses to adapt and embrace sustainable solutions.

II. Consideration Stage: Unpacking the Best Choices for Your Business

Sugarcane & PHA: The Gold Standard for B2B Sustainable Straws.

- Sugarcane Straws:

- Material: Made from bagasse – the fibrous byproduct of sugarcane juice extraction, repurposing agricultural waste. Some versions are 100% PLA-free.

- Manufacturing: Collection, drying, grinding, pelletizing, molding/extrusion, finishing (heat-treated for durability).

- Benefits: Utilizes agricultural waste (circular economy), home compostable (3-6 months), excellent durability (no sogginess for hours, up to 90°C), neutral taste, non-toxic, free from BPA/PFAS. Learn more about our sugarcane straws.

- PHA Straws:

- Material: Produced by microorganisms fermenting renewable resources like sugarcane molasses or plant-based oils (e.g., canola oil). Bio-based polymer mimicking traditional plastic.

- Manufacturing: Microbial fermentation, extraction/purification, pelletization, extrusion.

- Benefits: Highly biodegradable (soil, home compost, industrial compost, marine environments), comparable look, feel, and performance to plastic, superior temperature resistance (up to 100°C), no microplastics, FDA-approved, non-toxic. Nature Poly offers insights into PHA production Nature Poly.

Choosing Your Green Edge: A Comparison of Eco-Friendly Straws for Businesses.

Sugarcane vs. PHA vs. Others:

| Feature | Sugarcane Straws | PHA Straws | Paper Straws | PLA Straws (for context) |

|---|---|---|---|---|

| Primary Material | Bagasse (sugarcane fiber) | Fermented plant sugars/oils | Wood pulp/paper | Polylactic Acid (cornstarch, sugarcane) |

| Composition | 100% Plant-based, often PLA-free, PFAS-free | 100% Bio-based plastic, PFAS-free, BPA-free | Paper, potentially PFAS-coated | Plant-based bioplastic, often needs industrial compost |

| Durability in Liquids | Excellent (soggy-free for hours) | Excellent (like traditional plastic) | Prone to sogginess, can affect taste | Sturdy, but can warp in hot drinks |

| Hot Beverage Tolerance | Up to 90°C | Up to 100°C (superior) | Under 60°C (uncoated) | Can warp in hot drinks |

| Compostability | Home & Industrial (90-180 days) | Home, Industrial, Soil, Marine | Varies (coated vs. uncoated), often industrial | Primarily industrial |

| Taste/Odor | Neutral | Neutral (like plastic) | Can impart “papery” taste | Neutral |

| Cost | Cost-effective (especially in bulk) | Higher initial cost, but improving | Can be 10x plastic, but improving | Varies |

| Environmental Footprint | Low, utilizes agricultural waste (circular) | Low, reduced GHG vs. plastic, no microplastics | Higher (some production, PFAS concerns) | Better than plastic, but composting limits |

Market Momentum: The Growing Adoption of Biodegradable Straws.

The global eco-friendly straws market is not just a trend; it’s a rapidly expanding sector, estimated at $12.3B in 2025 and projected to reach $25.1B by 2035, showcasing a 7.3% CAGR. PHA straws are experiencing robust growth with industry experts estimating a market size of approximately $50M in 2025, with a projected 15-20% CAGR from 2025-2033. Hospitality businesses are actively transitioning to these alternatives, with studies showing increased customer satisfaction.

Major companies like Starbucks and McDonald’s have publicly committed to phasing out plastic straws, driving this trend further. This reflects a larger movement toward sustainability in hospitality, detailed in reports like this one from the EHL Insights EHL Insights.

Navigating the Regulatory Maze: US vs. EU Landscape.

- United States:

- Patchwork of Policies: There is no single federal ban; instead, a variety of state and local regulations govern straw usage.

- Federal Reversal (2025 context): An executive order was signed to end paper straw procurement and disfavor plastic alternatives in federal agencies.

- State & Local Leadership: Despite federal actions, states like California, Maine, and New York continue to enforce “straws upon request” or outright bans. Fort Myers Beach and Charleston specifically require marine biodegradable or ASTM-certified compostable straws.

- Controversies: The inconsistencies create compliance challenges. Some states preempt local bans, while cities like San Francisco have banned even “compostable plastic” (PLA) if not truly non-plastic. PFAS presence in some paper straws also raises concerns.

- European Union:

- Unified & Stringent: The Single-Use Plastics Directive (SUPD) has banned plastic straws (effective July 2021), regardless of “bio-sourced” or “biodegradable” labels.

- EPR Schemes: Producers are responsible for waste management and clean-up costs.

- Strict Definition of “Biodegradable”: The SUPD focuses on true environmental degradation, not just industrial compostability, particularly for items likely to enter the environment.

- Future Targets (by 2025/2026): Ambitious targets for plastic bottle collection and recycled content, along with new packaging regulations reducing waste.

- The “Biodegradable” Controversy: Understanding that “biodegradable” doesn’t always mean easy or fast degradation in all environments. The need for clear certifications like those from the Biodegradable Products Institute Biodegradable Products Institute and proper waste infrastructure.

III. Decision-Making Stage: Empowering Your Sustainable Sourcing Strategy

Beyond Compliance: How Sustainable Straws Drive Business Value.

- Enhance Brand Reputation & Attract Eco-Conscious Consumers: Over 70% of consumers prefer sustainable brands, enhancing your brand and building customer loyalty.

- Future-Proof Your Operations: Proactive compliance with evolving regulations avoids penalties and ensures market access.

- Improve Customer Experience: Durable, taste-neutral straws eliminate common complaints associated with soggy paper.

- Contribute to a Circular Economy: Utilizing agricultural byproducts and truly compostable materials reduces waste and carbon footprint.

Choosing Your Partner: A Comprehensive Supplier Evaluation Checklist for Sugarcane & PHA Straws.

- 1. Product Quality & Consistency:

- Verify genuine sugarcane bagasse and PHA composition.

- Request certifications: PLA-Free, PFAS-Free, BPA-Free, FDA-approved.

- Conduct in-house durability/performance tests across beverage types (hot, cold, thick).

- Assess consistency across batches.

- 2. Certifications & Compliance:

- Look for BPI, TÜV OK compost INDUSTRIAL/HOME, DIN CERTCO, ASTM D6400/D6868, USDA BioPreferred, ABA Seeding Mark.

- Ensure food safety standards are met.

- 3. Manufacturing & Sustainability Practices:

- Inquire about energy, water, waste management in production.

- Verify ethical sourcing of raw materials.

- 4. Supply Chain Reliability & Logistics:

- Assess lead times, MOQs, delivery frequency.

- Evaluate packaging efficiency and sustainability.

- 5. Cost & Value Proposition:

- Compare competitive pricing.

- Demand transparent pricing (no hidden fees).

- Consider Total Cost of Ownership (TCO) including waste savings.

- 6. Customer Service & Support:

- Evaluate responsiveness and communication.

- Inquire about dedicated account management.

- Understand return and issue resolution policies.

- 7. Reputation & References:

- Research industry standing, awards, testimonials.

- Request client references from similar businesses.

Spotlight: Momoio Sugarcane Straws PLA-Free – A Top Choice for B2B.

As a leader in the compostable straw market, Momoio offers sugarcane straws that are 100% natural plant-based, biodegradable & garden compostable, free from chemical & toxic & plastic, soggy-free up to 24 hours, suitable for both hot (90°C) and cold drinks, and affordably priced, making them an ideal solution for businesses prioritizing sustainability and performance. Check out our ranking in this list of top compostable straws Top 10 Compostable Straws.

IV. Future Outlook: Beyond 2025 – Continuous Innovation & Global Impact

- Emerging Innovations in Biodegradable Materials:

- PHA Production Advancements: Genetic engineering for high-yielding microbial strains, new substrates (food waste, cyanobacteria).

- Novel Plant-Based Materials: Seaweed-based, rice straws, coffee ground straws, coconut straws, cellulose acetate.

- Enhanced Performance: Improved water-resistant coatings, design for aesthetics and user appeal.

- Projected Market Trajectories:

- Continued robust growth in global biodegradable straw market (23.2% CAGR to 2031).

- Significant regional growth in North America (40%+ market share, 21.4% CAGR) and Europe (30%+ market share, 21.7% CAGR), driven by regulation and consumer demand.

- The Broader Sustainability Movement in Hospitality:Hotels are moving towards carbon neutrality, integrating AI for resource management, sustainable design, and circular economy initiatives (e.g., refillable amenities, food waste valorization). This reflects a shift from sustainability as a “marketing add-on” to a “cost-avoidance strategy” for procurement, driving efficiency and resilience.

Take the Next Step Towards a Greener Future.

Evaluate your current straw usage and environmental impact.

Contact Momoio today to request samples of our cutting-edge sugarcane and PHA biodegradable straws and receive a personalized consultation.Contact Us

Join the growing number of businesses leading the charge in sustainable hospitality.